Products

Barrier Display Film (BDF), Barrier Shrink Bags (BSB) For fresh meat packaging & Poultry Film

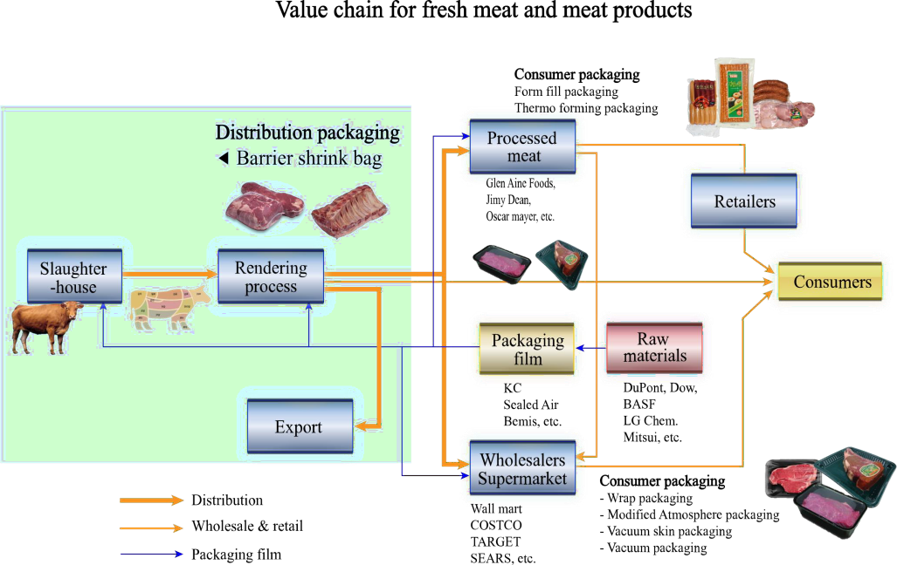

APPLICATIONS

Characteristics of MLF’s BSB

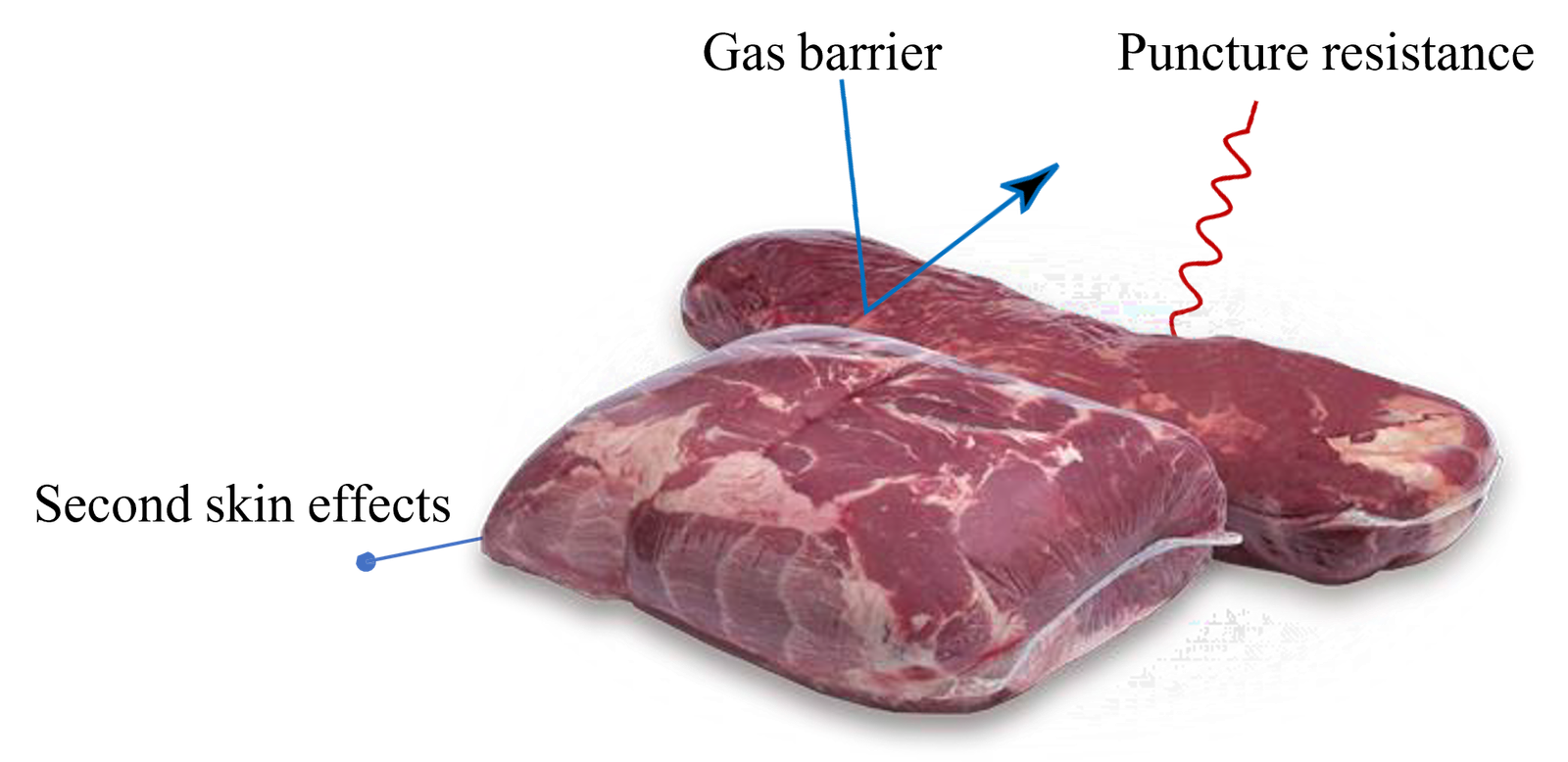

◆Excellent oxygen barrier & water vapor barrier

-Prolong the self life of fresh meat

-Reliable heat seals

◆High shrinkage & low temperature vacuum formability

-Tight packaging to produce second skin effect

-Minimize blood drip loss

◆Excellent impact and pin-hole resistance

– Resistance against abuse

Characteristics of MLF’s BDF

◆Excellent oxygen barrier

-The EVOH layer ensures an excellent barrier to oxygen and gases, ensuring longer shelf-life to the packed products.

◆Reduced shrinkage in both directions

-Creates a the “drum effect” on tray

-Ideal for packaging fresh meat products on a tray

◆Easy and reliable sealability to PE

◆Excellent optical properties: transparency and gloss

◆Great machinability.

Products

Type | Thickness (um) | Main Usage |

MLF-N05 | 50~70 | •Boneless fresh meat  |

MLF-O05 | 50~70 | •Boneless fresh meat  |

MLF-B05 | 70~110 | •Overlap heat sealable  |

◆ Standard bag size

- width; 250-700mm (interval ; 50mm)

- length; 250-1,000mm

◆ Round sealed bag, straight sealed bag

Top Stretchable Film

- The top web for chicken film is a crosslinked film with the below standard specifications:

- 2450 m * 350 mm * 20 microns

Specifications can be changed based on customer requirements